In terms of the preparations for Asian Winter Games 2025, Yabuli has attracted much attention as a key competition venue for snow sports. With the approaching Asian Winter Games and the influx of numerous people, the local sewage treatment was facing unprecedented challenges. Innovation Environment, a subsidiary of Chinayong Group, won the bid for this project, undertaking the task of upgrading the Yabuli Sewage Treatment Plant. Under tight time and arduous tasks, Innovation Environment successfully completed the installation and debugging work with professionalism and wisdom, ensuring the sewage plant can steadily operate and discharge standard effluent. Looking back on this journey, when facing every difficulty and problem, Innovation Environment gave perfect answers:

1. How did you finish the installation and debugging task on time under the tight project schedule?

The field staff of Innovation Environment worked on two shifts, respectively day and night shifts, ensuring 24-hours continuous operation. They always kept in touch with the customer’s technology department, the company’s technology department, engineering department and sales department to provide feedback and analyze situation in real time. All the staff worked hard against time to complete this project’s construction and debugging tasks efficiently and excellently in the shortest time. A professional project management team was assigned to carry out on-site maintenance work to ensure the normal operation during the Asian Winter Games.

2. How to solve the difficult construction conditions on the project site?

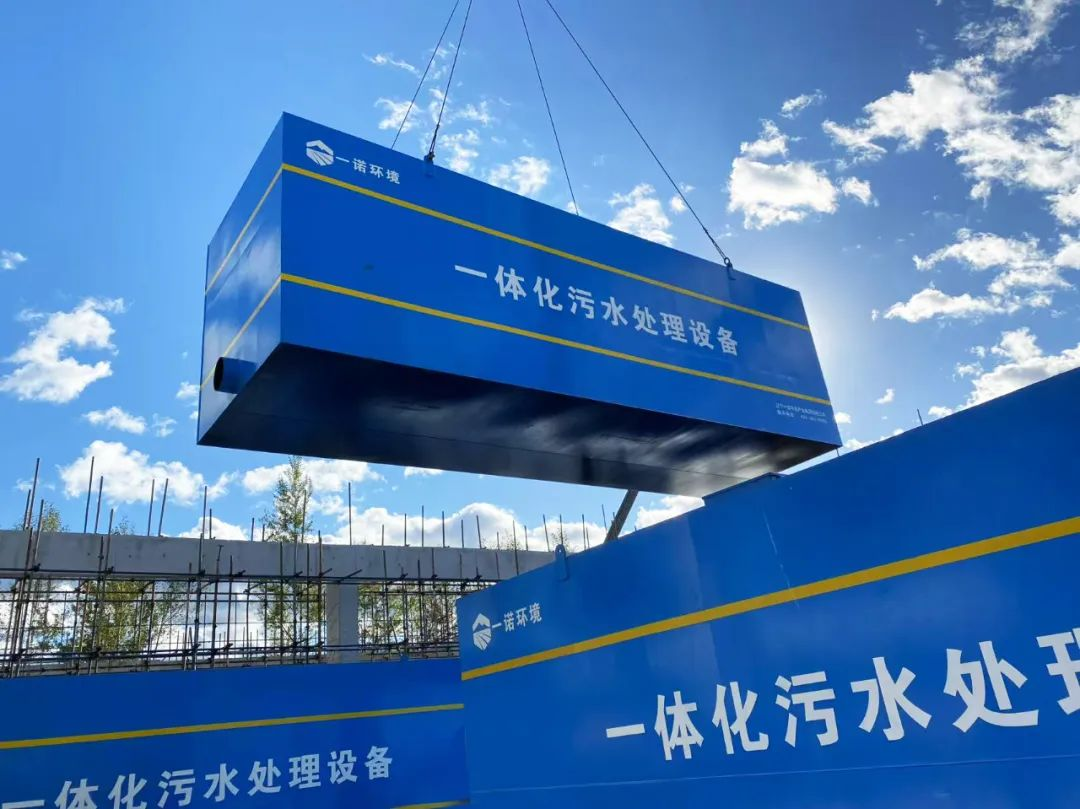

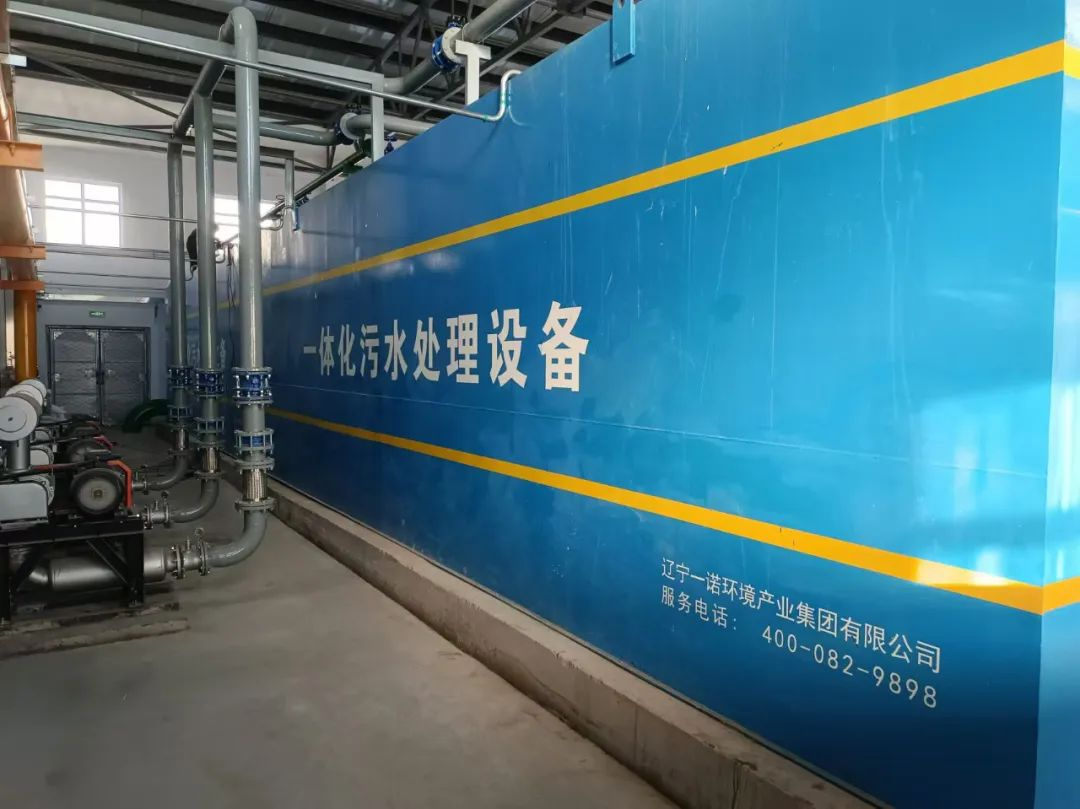

The modular assembly design created by Innovation Environment was adopted, and the equipment was highly integrated with full function, and occupied a small area. With precast assembly completed in the factory, the equipment was quickly installed on-site and put into service on time.

3. How to solve the difficulty in debugging and starting the biochemical system due to the cold winter and low water temperature in Yabuli, as well as difficulty in meeting the effluent standards?

Using the HF biological stuffing independently developed by Innovation Environment, microorganisms could maintain high activity in the biological stuffing and proliferate rapidly under suitable conditions. This not only effectively shortened the start-up cycle of the biochemical system, but also maintained high treatment efficiency under winter water temperature conditions of 5-10 ℃. That was how the effluent can stably reach the first-class A standard.

4. How to solve the problem of large changes in passenger flow and water volume between winter and summer?

A comprehensive regulating tank was set at the front end to cope with the change of water quantity and quality in different seasons, and the constant flow frequency conversion effluent technology was adopted to stably provide water for the subsequent biochemical unit system. The flexible control of anaerobic - anoxic - aerobic functions could be achieved by setting a precise zonal aeration device in the back-end biochemical area, which improved the adaptability of the biochemical system to different water qualities and quantities.

5. How to solve the shortage of onsite professional and technical personnel and the difficulty of operation and maintenance?

Innovation Environment adopted the IESC cloud platform, composed of intelligent hardware, new sensors and an information system independently developed by it, to realize the functions of online flow, liquid level pressure and other data monitoring, remote control and abnormal alarm, improved the efficiency of intelligent management and ensured the efficiency of production and operation.

6. How to ensure the effluent quality when the influent quality changes?

Using the HF biological stuffing independently developed by Innovation Environment can adjust and control microbial species and quantity quickly, supplemented by the flexible switching of treatment function of a multi-functional modular bioreactor, which could perfectly match the change of inlet water quality load.

7. How to ensure the quality of installation and debugging?

Quality monitoring was strengthened during the equipment installation process, to ensure that every step met design requirements and relevant standards. Clear acceptance criteria and processes were established to ensure the equipment met usage requirements after installation. During the construction process, we constantly summed up experiences and lessons to optimize construction methods and processes and improve construction quality and efficiency.

8. How to complete the equipment installation and meet the high standard quality requirements under the complex environment of a limited site and a staggered construction by multiple units?

According to the overall project plan, we have set a specific completion date for equipment installation and broken it down into key milestones, such as equipment arrival, hoisting in place, installation and commissioning, etc. We have developed a detailed equipment installation schedule plan based on the progress arrangements of multiple construction units, including daily, weekly, and monthly work content, personnel division, and time nodes.

Through the above questions, the technical and construction characteristics of this project are summarized as follows:

Accurate intelligent aeration system and flexible control ensure the adaptability of water quality and quantity

HF cold-resistant biological stuffing ensures the quality of effluent in low low-temperature environment

IESC cloud platform, intelligent management and operation

Process optimization, adapting to changes in water quality and quantity

Industrial design, integration of quality and aesthetics

Modular production, on-site assembly, improving efficiency

Multi-department cooperation, 24-hour installation and debugging

With the successful installation and commissioning of the project, Yabuli Sewage Plant has taken on a new look with its efficient and environmentally friendly attitude, guarding the purity and beauty of this ski paradise. Through this renovation, Yabuli Sewage Plant can not only calmly cope with the sewage treatment, but also lay a solid foundation for the long-term sustainable development of the local area during the Asian Winter Games, allowing the ice and snow resort to shine constantly.

Company Profile

Innovation Environment focuses on the research and development of advanced environmental protection technologies and the manufacturing of integrated environmental protection equipment. It has formed an “8+4” business model with eight product series and four operational services in the field of environmental governance. It was the enterprise with the most complete product line in the domestic environmental governance field and the largest production base in China. It has formed a leading and comprehensive one-stop product and service platform for environmental governance in China.

Eight products include:

1 Integrated sewage treatment equipment

2 Equipment integration of waterworks construction

3 Landfill leachate treatment equipment

4 Decentralized sewage treatment equipment

5 Sodium hypochlorite disinfection equipment

6 UED high-difficulty and high-concentration wastewater treatment device

7 Equipment for recycling livestock manure

8 Toilet revolution supporting septic tank

Four operational services include:

1 Managed operation and maintenance service of sewage treatment station

2 Leachate treatment services for landfills

3 Emergency sewage treatment service

4Treatment services for wastewater with high toxicity, high salinity and high concentration

Innovation Environment takes “beautiful China and green ecology” as its own responsibility. It was the first in China to put forward and implement the concept of a regional carbon cycle. It has integrated various R&D resources at home and abroad, and introduced advanced technology to help build beautiful China and faithfully guard the ecological environment!